No products in the basket.

Information

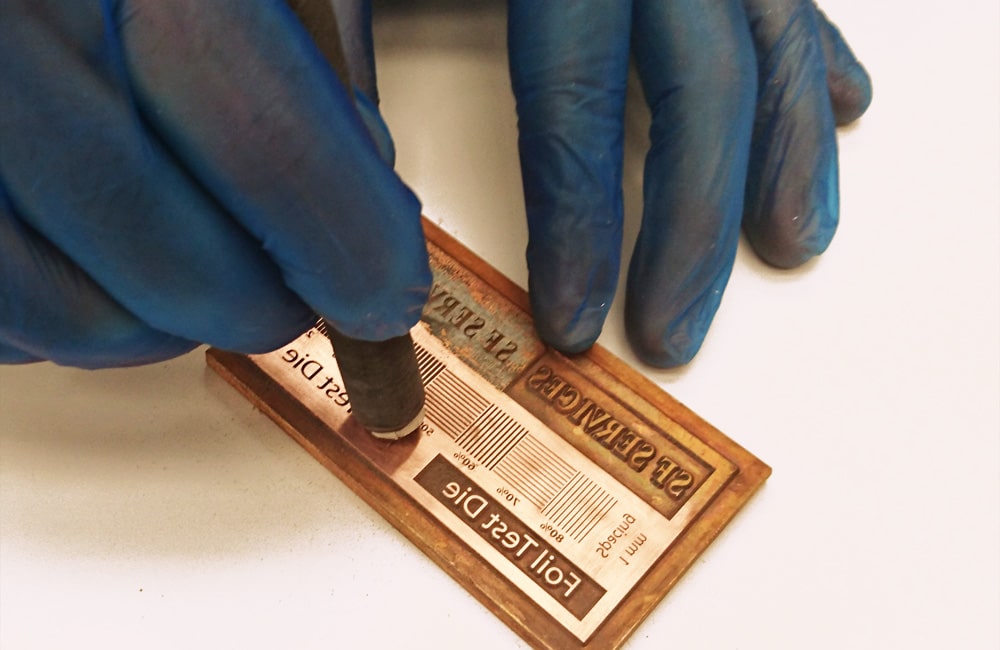

Clean your dies for a better foiling result

Before you begin foiling, it’s important to clean your dies (clichés), especially if they’re magnesium or copper foiling dies. To manufacture dies made from these materials, strong and corrosive acids are used during a chemical etching process and it’s not uncommon for residues to be left on the surface of the die. Unclean surfaces can cause reactions to the foil and substrates which can impact the quality of your foiled finish.

Cleaning is also essential to revitalise old or unused (stored) dies which have been affected by oxidation. Give them a good clean to bring them back to their original state. Obviously if you do this, it will save you time and money not having to remake new dies with your supplier and can help you quote a more cost-effective price for your work.

To clean your dies, you with need either a Garryflex Block or glass fibre brush / bristle brush.

Garryflex Block

Better suited for use with magnesium dies as they provide a more gentle cleaning process. They can also be used to clean dirt and oil in small hard to reach areas of your machine to stop any marking of sheets.

Glass Fibre Brush

A harsher brush for stronger metals like copper – not for magnesium. They will also remove small imperfections on the die surface, which can increase the quality of the foiled finish.

Brass Cleaning Brush

Brass Cleaning Brush

A soft brass bristle brush specifically chosen for safely cleaning, polishing and deburring brass foiling dies without damage. Particularly useful for fluted dies as the bristles are soft enough to flex and bend to reach into multi-level sections of your dies and not to harsh to cause damage. Can also be used to safely clean circuit boards and other electro static devices.

This Profoil brush has an easy-to-grip wooden, rectangular handle and offers an outer surround of neutral horse hair fibre to minimise overspray.