No products in the basket.

Uncategorized

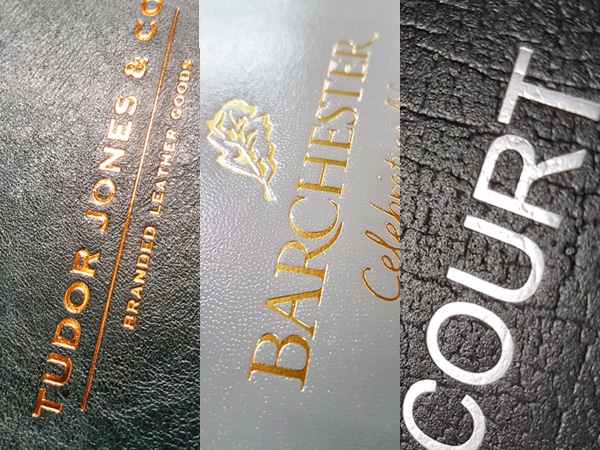

Hot Stamping Leather

We have seen a huge rise in the popularity of hot foil stamping leather materials in recent times, with many customers looking to launch a new product or embellish an existing product with a more luxurious and customised feel. You can hot stamp leather with metallic or coloured foils or use a stamp to deboss (push-in) the material to only create an indent of a design such as a company logo.

Hot Stamping Leather – What do I need?

Machines

To begin this process, you will firstly need a machine capable of stamping leather and if you’re looking to add foil to it, you need a machine with a heating plate system. Profoil’s ProPress 310 is the perfect beginner machine for both options; it’s simple to use and very easy to set-up. The machine can produce a maximum of 1 ton pressure which should be enough to stamp small logos into most leather materials. Some materials and larger images may require more pressure and if that’s the case, then we suggest looking at the ProPress 450 which is a pneumatic machine (meaning it uses compressed air) that produces up to 3 ton of pressure. These machines are primarily foil stamping machines and therefore provide the ability to run hot stamping foil through the machine.

Dies/Cliches/Stamps

The second item you’ll need is a metal stamp – otherwise known as a die or cliché. The type of die required for hot stamping leather is a foiling die because it will be manufactured with your image or logo “standing-up” off the back plate of the die.

Do not be confused with calling a “deboss effect” (stamping into a material) as an “emboss effect” – an embossing die is a different type of die completely which you won’t be able to use with leather.

When stamping into leather we always recommend brass dies. These types of dies are produced using CNC engraving methods and therefore it’s possible to achieve a deeper machined depth of your image, which is required because of the softness of the leather material – when stamping or debossing you’ll then have the ability to push further into the material giving you more definition of the image or logo impression.

Hot Stamping Foil for Leathers

Lastly, if you’re looking to add a foiled finish to leather, then you’ll need a specialist hot stamping foil for leathers as you cannot use any hot foil – it won’t sufficiently adhere to the material and will flake off easily. Regular hot stamping foils are produced for graphics materials only. Due to the natural textured surface and occasionally the use of curing/treating chemicals on leathers, this can make leather difficult for foiling so Profoil has specifically chosen to offer the Kurz AFS foils which perform brilliantly on both synthetic/faux leathers and genuine leathers. They also work well whether your design is broad or fine detail.

Hopefully this will give you a much better idea of what you need to get started when hot stamping leather materials. Working with leather can be fun and rewarding to see excellent results on your products, which can help make them stand out from the crowd. Belts, wallets, bags, bracelets, bag and watch/accessory straps are just some of the promotional items we often see stamped.