No products in the basket.

Information

Engraved Brass Dies

A large proportion of our business is creating dies – both hot foil stamping dies and embossing dies. Over time we’ve managed to build a reputation for quality and reliability, always ensuring each die is finished to our highest standards.

When it comes to embossing engraved dies, we commonly manufacture in magnesium, however we also offer more advanced results with brass production of embossing dies. Both materials have pros and cons for the job in hand. Magnesium is more cost-effective being the cheaper material, but due to the chemical etching manufacturing process of magnesium, there are limitations to the end result as the acid etching process does not allow for modification.

But with brass and our state-of-the-art CNC machinery, the options at which brass can be “sculptured” and engraved makes it the material of choice for unique and impressive finishes. Brass is also seen as the environmentally friendly option of all materials as it requires no chemicals to etch and is widely recycled.

The 3 main options of engraved brass dies Profoil can offer:

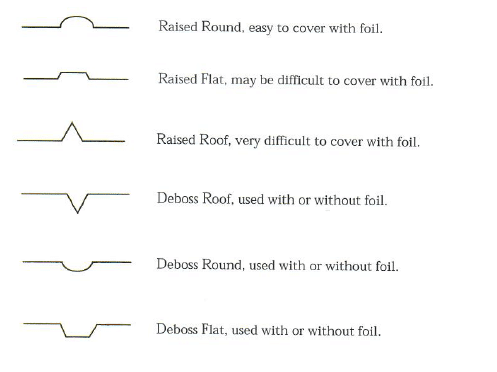

“Round” effect which means the bottomed-out base is sculptured to have soft, rounded edges as it connects to the flat profile of the face of the die. When embossing (or used with a fluted die) the emboss is smooth, and consistent, almost bubble like if embossing small areas. However larger solid emboss areas with the round effect will have a bottomed out flat in between, therefore can also be described more as a pillow effect.

The next option is a “Flat” effect which is achieved by machining an angled but straight profile towards the bottomed-out base. This results in a sharper angle as the base connects to the flat profile of the face of the die. This results in block-like features – perfect for large bold text where definition is wanted, however this can be slightly tricky to apply hot stamping foil if you have a fluted die (foil and emboss in one-pass).

The next option is a “Flat” effect which is achieved by machining an angled but straight profile towards the bottomed-out base. This results in a sharper angle as the base connects to the flat profile of the face of the die. This results in block-like features – perfect for large bold text where definition is wanted, however this can be slightly tricky to apply hot stamping foil if you have a fluted die (foil and emboss in one-pass).

The final option is a “raised roof” effect. This is achieved by sculpturing the brass to have a chisel point profile towards the bottomed-out base, like a “V” shaped indent in the die. This is very effective when properly implemented, for example, embossing straight, bold lines. However, is very difficult to achieve foil and emboss in a fluted die and therefore is only recommended for embossing.

These affects will also work with the reverse debossing process, so instead of the effect becoming a raised texture on your substrates, the deboss will indent into your material – best with thick, striking materials.

How to order engraved brass dies

If you would like to order or discuss your requirements for these specialist dies, then please contact us either by telephone on +44 (0) 1473 707222 or email our in-house dies studio at [email protected] with a copy of your artwork and some detail explaining your requirements.

We’re always more than happy to help!