No products in the basket.

Information

Die Ordering Guide – Important

Detailed Artwork Requirements:

We consider our die production service to be deemed as a fast, “one-stop” shop process. We produce your dies to the exact specifications that you provide us in your artwork. Your artwork must meet our minimum specifications and be correct.

We must receive your image formatted as 100% to scale, “two-colour” black on white only.

For magnesium dies, we recommend a minimum resolution of 300dpi. This is required to ensure we produce your die to a sharp, crisp image perfect for excellent foil impressing.

For any brass dies, we must have fully vectorised artwork with the outlines of text and images included – no shading, no gradients or anti-aliasing. Suitable colour separation should be provided for artwork files also used in print production.

File Types:

We can use .pdf, .eps, .ai files up to a maximum of 2.0mb. We are unable to accept .jpg (or JPEG) files. If you have correctly formatted your file, then it should, in almost all cases, be under the maximum file size of 2.0mb. Its important that all orders for brass CNC production are fully vectorised with all text saved as outlines.

Die Sizing:

To correctly size up your die when ordering online, please enter the width and height of the image on your artwork in centimetres (CMS) – 1 decimal place is accepted (rounding upwards). If you require a single die with multiple images on, please ensure you use the maximum outer points of your artwork.

Please enquire for die grouping orders, as these cannot be processed with online orders.

Our maximum magnesium die production size is 55cm x 45cm.

Our maximum brass die production size is 100cm x 50cm

Our maximum copper die production size is 72cm x 57cm

Please be as accurate as possible when measuring your artwork width and height. Artwork submitted which is larger than that detailed on your order, will incur additional charges and may delay production of your die.

Please note that we may reject or contact you regarding an order for particular die materials and die sizes which still fit within our maximum die sizes stated above. Chemical etching is not an exact science and highly detailed artwork and reversal images can be more difficult to etch as die sizes become larger.

Bleed space:

When ordering online, please do not add any extra bleed/waste space. We automatically allow 6mm for foil blocking dies and 10mm for embossing all around your artwork within our pricing structure.

Die Reading Pane:

Please note we automatically reverse your artwork during our die production process. Therefore, and in most normal circumstances, to produce a correct reading foil image you should supply correct reading artwork. The die you will receive will be reversed.

Visual Guideline:

Die Etch Depths:

Unless you inform us either during your online order or before the commencement of your die production, all dies are made to our standard (most popular) etch depths. You can request a deeper etch if need be – often useful for leather stamping. Please see the table below for specifications.

| Material | Standard Etch | Deep Etch / Deep Machined | Extra Deep Machined |

|---|---|---|---|

| Magnesium | 2mm | 2mm is considered deep | |

| Copper | 0.7mm | 0.7mm (subject to artwork) | |

| Brass | 2mm | 2.5mm (subject to artwork) | 3mm (subject to artwork) |

IMPORTANT NOTE: When you request deep etch, depth remains subject to artwork. We will do our very best to achieve the deeper etch, but it is not always possible in artwork which contains complex layouts and very thin, small fonts/detail/lines. We will continue to manufacture the die to the best depth possible above our standard depth, but you will not be notified. If you specifically wish to achieve a required depth not listed online, please check your artwork’s suitability first with staff on [email protected].

When requiring constant etch depths of greater than 2mm, then you will most likely need to be ordering brass dies where the depth of the image can be made consistent through CNC programming. There is also minimal shouldering with brass CNC manufacturing, unlike etching.

Registration Marks:

Please note that unless otherwise specified, all registration (tick) marks are removed from your artwork. In the instance that you would like your finished die to include the registration marks, please inform us and ensure that the dimensions of your calculated/priced artwork now includes these marks. Please also ensure marks are provided in the same single colour as your main image, in case of colour separation.

Cutting Marks:

If you require a die to be cut to a specific size, please include Trim/Guide Marks on your artwork – like the example below. You can easily create these within Adobe Illustrator by creating the Artboard the same size as the die that you require cut, and saving the PDF file with Trim marks under “Marks & Bleeds” when saving. Please ensure that the dimensions of your calculated/priced artwork online is now measured to include these cut marks. Please also ensure marks are provided in the same single colour as your main image, in case of colour separation. DO NOT CREATE SOLID LINE, SQUARE/RECTANGLE BORDERS as this will be assumed to be part of your artwork and will be included on the die.

Pre-drilled Holes:

You may mark your artwork with pre-drilled holes and add the cost of the holes to your order. Please note that the labour charge for adding in holes is displayed on the dropdown option on the product page, but only accumulated with the cost of your die once you have added the die to your shopping basket.

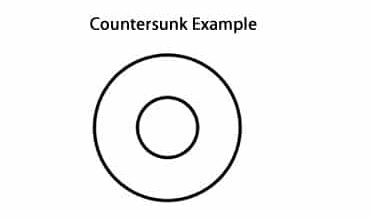

We can accommodate standard drilled holes and also countersunk holes. For countersunk, please ensure you artwork details both the diameter of the upper (outer) and lower (inner) holes, which will inform us of the pitch of the countersunk hole. Your artwork must be 100% to scale and have the following dimensions.

Magnesium dies only:

M4 countersunk screw hole – outer 8.5mm circle, inner 4.5mm circle (4mm, 6.35mm & 7mm gauge only)

3mm hole – 3mm circle (on 1.63mm dies only)

Brass dies:

Any size countersunk drill hole can be achieved via our CNC machine.

Please note that all countersunk holes must be a minimum distance of 15mm from the centre of your countersunk hole to any part of your artworks imagery. Any less, and your machined image may be damaged during the machining of the countersunk hole.

Debossing or Embossing:

There are two different visual effects available to create basic textures on substrates using tooling provided by Profoil.

Embossing, otherwise known as “blind embossing”, creates a raised print surface on your substrate. To create this effect, you should order an Embossing Die from our online range. Embossing dies can come with hard or soft resin counterforce, or without a counter if you have materials to make your own or purchase materials from our counter die production range.

The opposite is debossing, which creates an inward print surface on your substrate. To create this effect, you require a standard foil stamping die, preferably with a deep-etch. You can then push the die into the substrate. For any leather debossing, we recommend you use Brass as the material choice for your die as we can create the deepest of etches up to 3mm through CNC machine production. We will always reduce our foiling and embossing dies by a set percentage to allow for heat expansion when on press, so if you are registering to print, please specify no heat expansion when ordering to ensure the die will be 100% to scale.

Die Ordering Terms:

We cannot offer refunds or offer re-production of dies free of charge for inaccurate or poor quality dies that we consider to have been caused by errors in your submitted artwork. We produce each die exactly as per your artwork and recommend that our detailed requirements are always adhered to before you submit your order.

Each die that we produce has to pass our own internal quality inspection process and any flaws or imperfections will be highlighted and also cross-referenced against your artwork.

Delivery Schedule for Dies:

If you place and order which includes both die and non-die products, your full order will be despatched in-line with the following delivery schedule, on the basis that your original supplied artwork is deemed “print-ready”. If we request changes and a re-supply of artwork from you, then the delivery schedule will come into force at the point when we receive a sufficient “print-ready” artwork file from you.

Magnesium and Brass Foiling dies – If we receive your order by 12.00pm, we will have your order packed and shipped the same day. Orders received after 12.00pm will be shipped on the next business day. For EU customers, our same day service is restricted to 10.30am.

Magnesium and Brass Embossing dies – If we received your order by 11.00am, we will have your order packed and shipped the same day. Orders received after 11.00am will be shipped on the next business day. For EU customers, our same day service is restricted to 10.30am.

How To Order Dies Online:

Ordering dies from Profoil couldn’t be simpler – despatch of your dies is just a few clicks away.

- Select the die material and gauge size you require, by choosing the relevant product from the navigation

- On the product page, enter your die width and height in the Die Calculation section using the drop down options – select the nearest value ROUNDING UPWARDS in centimetres and then the price of your die will be displayed. The width and height must match your artwork.

- Add whether you wish to choose a standard or deep etch (See details below)

- Add any comments that you wish to add to the order

- Click “add to cart & upload files”, where you will be directed to the artwork uploads page

- Click the “select files” button to navigate to your artwork file and attach it to your order. Remember your artwork MUST BE TO SCALE and match your Die Calculation dimensions.

- When you see the success message, you may continue to your cart or continue shopping on the site

View the video guide below.

Your order number is for your own use and will be included on all paperwork from Profoil. Any delay in providing your artwork will effect production time.

We offer a broad range of metal gauges. In the UK and USA 6.35mm is the most popular gauge size, whereas Europe and other International states are mostly 7mm. It is important to check the gauge required before ordering.

Rigid counter-forces are 0.8mm and Flexible counter-forces are 0.125mm-0.4mm.